The Essentials for Preventing Moisture Related Flooring Failures

Freshly poured concrete contains a lot of water, making it extremely important to test a concrete slab’s moisture condition before the flooring installation.

Previously published by Premier Flooring Retailer

If you’re a general contractor or flooring professional responsible for installing floor coverings there’s one thing you must always pay attention to: moisture.

Moisture is the industry’s most commonly recurring and expensive flooring-related problem. Unfortunately, it’s a problem often overlooked or neglected.

Consider these alarming facts: According to Robert Nieminen, Editor-In-Chief of Interiors + Sources magazine, U.S. commercial property owners spend an estimated $2.4 billion annually on remediation of structures and floor coverings due to moisture-related flooring failures. Additionally, Nieminen remarks that $1.2 billion is spent for unplanned topical moisture treatments needed to address moisture issues before floor coverings are installed.

And let’s not forget added project costs incurred because of project delays, flooring replacement, lost revenue associated with business disruptions, litigation, and loss of reputation.

Nearly every flooring product is affected in one way or another by excess water vapor emissions from concrete and accompanying pH issues – be it carpet, laminate, rubber, tile, vinyl, or wood. Moisture damage to flooring materials includes debonding, warping, buckling, peeling, adhesive degradation, cupping, gaps, mold growth, and more.

Moisture damage may also compromise other essential building materials besides flooring such as studs, floor support beams, and sheetrock.

Measure Wood Flooring Moisture

Wood flooring and wood subfloors must be measured for excess moisture since wood easily absorbs moisture from concrete slabs and its environment. This moisture can be extremely damaging. In fact, the National Wood Flooring Association (NWFA) estimates that at least 75% of all installation failures result from moisture problems.

For best results, flooring professionals and general contractors should measure wood flooring for moisture before, during, and after installation using an accurate moisture meter. Accurate moisture measurements enable them to avoid costly legal claims, loss of reputation, customer dissatisfaction, and the cost of replacing damaged materials.

Measure Concrete Moisture

Since moisture is present in all concrete slabs – new and existing – it will interact with flooring materials and the environment as it comes to the surface. So moisture in concrete floor slabs must be measured before installation to avoid flooring failures. Moisture measurement helps determine if all flooring materials – coverings, adhesives, primer, patching compounds, and the wood flooring – are compatible with existing moisture levels.

In fact, the World Floor Covering Association (WFCA), the Floor Covering Installation Contractors Association (FCICA), and many others in the industry have repeatedly stressed the importance of independent, accurate, and reliable moisture testing of concrete floor slabs.

Based on scientific studies, the most accurate and reliable method for determining a concrete slab’s moisture condition is to identify its internal relative humidity (RH). RH testing is crucial because it measures moisture below the surface of the concrete slab. Other tests, like anhydrous calcium chloride, are surface-based and do not give reliable results.

What Is Relative Humidity?

Relative humidity is the ratio of the actual pressure of water vapor in the air compared to saturation water vapor, which is expressed as a percentage.

Simply put, RH is the amount of moisture that we feel in the air compared to what the air could hold if it were 100% saturated. At 100% saturation, the air could not contain any more water vapor at the current temperature. Whereas at 80% RH, the air holds only 80% of the water vapor it can hold at the current temperature.

Measuring RH in a concrete slab is simple. It involves measuring a small volume of air at the bottom of a hole drilled into the slab. This provides an accurate measurement of the moisture condition of a slab and indicates when a slab has reached the desired dryness for finishes.

How to Determine RH in Concrete Slabs

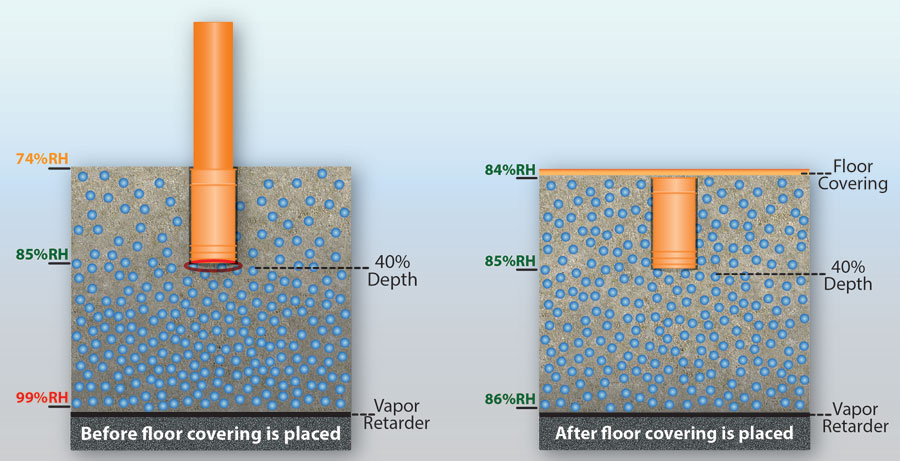

RH testing is depth-specific, which helps explain why it reliably predicts the amount of moisture that the finished floor will “see” after it is placed.

ASTM F2170, the standard test method for determining RH in concrete slabs, involves placing in-situ RH probes at specific depths in the slab. After allowing the RH probes to equilibrate, measurements of RH are taken to assess the overall moisture condition of the slab. Once the probes are placed within the slab, they’re less susceptible to environmental or ambient changes at the surface like surface-based tests.

This test method also provides more predictive test data as long as the building is acclimated at or near the “service” temperature and RH levels anticipated during occupancy or use. To ensure accuracy, “service conditions” of the environment must be maintained for a minimum of 48 hours before concrete testing begins and for at least 24 hours during the actual RH testing.

Because of its accuracy in predicting true moisture conditions with a slab, some resilient flooring manufacturers exclusively require in-situ RH testing, while others list it as the preferred test method.

Free Download – 4 Reasons Why Your Concrete Is Taking Forever to Dry

Moisture Measurement Tools

A number of great tools are available to general contractors and flooring installers for measuring moisture in wood and concrete. The use of three tools, in particular, can help prevent moisture-related flooring problems:

Data loggers like the Smart Logger from Wagner Meters can provide continuous monitoring and recording of ambient temperature and relative humidity conditions. Readings from the Smart Logger can be downloaded to a smart device via Bluetooth® connection and analyzed. The results can be emailed or printed as reports.

- In-situ RH test kit for assessing the moisture condition of concrete floor slabs. These test kits are easy to use, fast and highly accurate. The Rapid RH starter kit by Wagner Meters is the most popular of the kits available and offers technologically advanced options such as the DataMaster app for mobile devices.

- Data logger for remote monitoring of ambient relative humidity and temperature. This is a small, portable device that’s extremely useful for tracking ambient conditions 24/7, even when you are away from the job site. Options include Wagner Meters’ all-new Smart Logger, which can store thousands of temperature and RH measurements.

- Hand-held moisture meter for measuring the moisture content of wood flooring products and determining readiness for installation. One of the newest options is Wagner’s Orion series of pinless wood moisture meters that come with exclusive on-site calibration, ensuring consistent accuracy throughout the meter’s lifetime.

For More Information

Learn more about Wagner Meters’ Rapid RH, Smart Logger, and new Orion moisture meters – ideal moisture solutions for any flooring job. Give us a call worldwide toll-free at (541) 291-5123.

Jason has 20+ years’ experience in sales and sales management in a spectrum of industries and has successfully launched a variety of products to the market, including the original Rapid RH® concrete moisture tests. He currently works with Wagner Meters as our Rapid RH® product sales manager.

Related Posts via Taxonomies

Last updated on June 8th, 2021