Optimizing Kiln Performance with In-Line Moisture Measurement

In producing an effective kiln-drying program for lumber, comprehensive analysis of your wood moisture content should be the number one concern.

That’s obvious, you’re probably thinking, but what is less obvious is the number of key points in the manufacturing process where moisture content can and must be monitored in order to optimize kiln performance. Moisture measurement at various points in the process is crucial, but post-kiln moisture measurement of all of your incoming lumber prior to further processing provides the greatest insight into how efficiently and effectively your kiln operations are drying. Post-kiln moisture measurement also gives you the additional important benefit of catching pieces of lumber that do not meet your critical moisture requirements before they are processed down the line.

In-Kiln Moisture Measurement Systems: Real-Time Measurement, Not Data Analysis

In-kiln moisture measurement systems are purely real-time measurement tools that provide moisture content readings to, at best, assist in the kiln control systems’ drying program. In-kiln moisture measurement systems typically use a maximum of 8 sensors, measuring a tiny fraction of the kiln load to provide real-time feedback to the kiln operator or kiln control system through the moisture content sensor readings. Along with the measurement of equilibrium moisture content during the drying process, they can be a valid tool to assist in determining when a kiln load (charge) is ready to pull or to assist in real-time changes during the drying process.

These systems, though, are not comprehensive moisture data collection quality control tools. Ultimately, the immediate goal of an in-kiln moisture measurement system is to help operators determine when the lumber of a particular charge has reached its target moisture content range, not to perform comprehensive kiln drying or moisture quality analysis.

On the other hand, In-line moisture measurement systems in the processing plant or planer mill can measure all of the dried lumber early in the process and are ideally positioned to collect important moisture metrics about the upstream drying process. Data collected from these systems can provide truly comprehensive moisture data on a charge-by-charge or product run basis to assist in fine-tuning the kiln drying process.

Free Download – How to Choose a Moisture Measurement System for Your Sawmill Buying Guide

In-Line (In-Process) Moisture Measurement Systems: Getting the Big Picture with Comprehensive Data

With an in-line moisture measurement system, every single board in the production chain can contribute to your moisture quality evaluation. With a sample size that encompasses all of your lumber from all of your kilns, you should be able to determine at minimum two major indicators of your kiln process performance: a standard deviation (loosely defined as the variability in moisture content on a per charge basis), and a percentage of unacceptably wet and dry lumber.

1. Standard Deviation

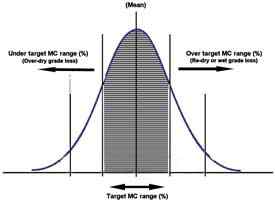

Standard deviation both visually and numerically demonstrates the variance of a kiln’s performance on a charge by charge basis. In thinking of the traditional bell curve representation of standard deviation, the smaller the range from the target moisture content to the actual post-kiln results, the better the kiln performance and, therefore, the better the grade production for each kiln and charge. Obviously, there will always be lumber that falls outside the target range but an optimized kiln set up should reduce the number of board feet that miss the target moisture content significantly.

Standard deviation becomes statistically significant when a history of data can be examined, both on a kiln-by-kiln basis and on a charge-by-charge basis. If a particular kiln regularly demonstrates a higher standard deviation compared to other kilns, it may indicate a maintenance issue, or possibly even an operator issue that can be addressed through further training. Tracing the standard deviation of different species or even specific suppliers of green lumber can allow initial kiln setups to be optimized for each charge. Simply put, the standard deviation can help point you in the right direction when asking why the data is the way it is.

Tracking standard deviation is a good indicator of potential drying changes that may improve kiln performance. A mechanical change (i.e. reversing air flow more frequently) or a procedural change (i.e. adjusting the venting schedule) may be all that is necessary to improve the standard deviation for a particular kiln and to prevent over-dry or over-wet lumber. If you have a very specific moisture content target, additional practices like stacking procedures or schedule variance for different species may also become important. But overall, the lower the standard deviation, the better the process.

It should be noted that there are potential limitations with using standard deviation in traditional QC standards. A 2007 Wagner Meters study demonstrated that standard and average deviation was found to be unreliable for determining optimum kiln drying targets for softwood grading targets. Put briefly, a similar average moisture content (MC) reading between separate charges does not always indicate the same lumber value. This observation led to a six-sigma process that Wagner Meters refers to as “lognormal statistical analysis”. While this application has not been extensively tested for hardwood applications, it may merit further examination for data that falls outside the expected norm.

2. “Wet” Lumber

Lumber that finishes over the maximum acceptable moisture content is obviously going to be problematic. The costs in kiln time for re-drying and re-milling create a difficult balance when considered against the business loss through grade loss, sort or mold issues and regrade claims. The obvious response is to increase drying time in the kiln if this number is consistently high. But the risk of overdrying presents just as much a challenge for target product production. The obvious correlation between moisture content and grade recovery possibly presents the strongest case possible for the necessity of an in-line moisture measurement system. With a larger sample size, and with the right assessment and reporting tools integrated with an in-line system, kiln performance can be analyzed and corrected to find that “sweet spot” – the ideal drying conditions that come with optimized kiln performance.

Developing the Data

There are a variety of in-line moisture measurement systems available and very few mills or secondary wood products processors operate without one. Integration of specific components is obviously important but the real key to success comes in making the best use of the data collected for real-world insight into kiln drying performance. Optimization means being sure the cycle of information is moving smoothly. And this is where your kiln operators or data collection specialist becomes crucial.

There are a number of questions to ask in order to turn data collection into practical insights:

1. Are we maximizing utilization of our moisture measurement?

Is your in-line moisture measurement system in continuous operation to maximize data collection? Is your system automated to record the data collected? Statistically, significant monitoring is dependent on the volume of data collected, as well as the consistency in the process point where it is collected. The more data you have to assess, the greater the insights into your kiln drying operations.

2. Who is responsible for collecting and assessing the data?

In some mills, moisture content levels are monitored by graders; in others, by Quality Control (QC); in others, by kiln operators. Once data is collected, there also needs to be an ability to sort the data by relevant categories such as a particular kiln, dimension and/or species, date of kiln load, etc. There are a variety of assessment and reporting tools available on the market that offer a wide range of reporting options, but ultimately the reports also need to be used to drive and optimize the kiln drying process.

3. How are changes implemented?

As in any large production enterprise, communication of the findings needs to be clear in order to produce effective and productive change. Ideally, there will be several people trained in operating your in-line moisture measurement system so that assessment, the parameter set up, and kiln set up changes can be handled promptly and accurately in response to the data reports.

Putting the Data to Use

The ultimate goal of data storage and analysis in kiln performance is not just to maximize charge times or kiln maintenance issues, but to be able to see each step of the drying process achieve the optimum lumber grade percentages possible. Particularly for mills that do not make use of a redrying process for over wet lumber, finding the optimal set-point for the kiln process can mean even higher savings in lumber grade value.

In-line moisture measurement systems also offer other very practical features for mill operations. For example, Wagner Meters Omega In-Line Moisture Measurement System offers up to four programmable moisture limits that can trigger spray marking systems to quickly and accurately mark lumber that has not met the moisture content specification. This lumber can be easily identified and turned around for re-drying or re-milling as necessary. In-line systems also offer set-up and calibration records for different wood products that can be easily implemented through a PC or desktop and produce batch reports, kiln settings at a glance, moisture content limit alarms and more.

When a history of specific data is collected for a particular kiln, it is also possible to use the data to create a 3D representation or moisture content ‘Color map’ of a kiln to help identify kilns with potential maintenance issues or performance issues. It is a fact that there are no hard and fast rules for guaranteeing every charge will respond identically to the same conditions, but with significant data records, trends can be mapped to target specific issues or variables more quickly and responsively. Even if the information only means a reduced number of shutdowns for manual checks in the kiln, the cost savings in energy consumption would be significant.

For specific kiln situations, data from an in-line moisture measurement system can also have a practical application for kiln operation. For a mill that routinely runs charges with mixed species or mixed dimensional lumber, an accurate picture of the kiln performance can impact the kiln schedule or processes for any given charge.

Optimization on the Mill Floor

The process of drying lumber is, without question, as much an art as it is an exercise in data tracking. The myriad of ways moisture data can be applied makes a proper assessment and reporting tools a must to any company looking to optimize kiln performance while increasing product quality. With a robust and integrated in-line moisture measurement system, your kiln drying results and the quality product you deliver to your end users can be a work of art.

As Sales Manager for Wagner Meters, Ron has more than 35 years of experience with instrumentation and measurement systems in different industries. In previous positions, he has served as Regional Sales Manager, Product and Projects Manager, and Sales Manager for manufacturers involved in measurement instrumentation.

Related Posts via Taxonomies

Last updated on June 7th, 2022

Do you think this process could work as a inline moisture mapping for OSB? Could you send me some examples of the 3d plot as well?

Hi Kyle,

Please give me a call at (800) 634-9961 ext. 225 to discuss this.