Grapeview Point Boat Works Relies on Wagner to Measure Moisture

The building frame on the left is for a 14′ sailboat, design name “Swallow.”

At the south end of an inlet, in the heart of vacation home paradise, is Puget Sound. Found here is Washington’s Grapeview Point Boat Works, a wooden boat restoration, boat repair, and new build business. Owner Tom Regan, formerly an electronics and manufacturing contractor, started the 17-year-old company by happy accident.

“I was out for a row one day, and upon hearing that I built the boat I was rowing in, a fellow rower asked if I built boats for other people,” he says. “I went out that week and got a business license.”

Regan builds 15- to 20-foot custom wooden sailboats, rowboats, and canoes for customers who are people like Regan – busy professionals who grew up with wooden boats in the family. He also works off-site at local marinas on boats up to 30 feet in length.

“The business is 50/50 in terms of new construction versus restorations here in the shop and work out in the field doing repairs and upgrades,” he says.

His boat maintenance and restoration skills are often called upon to do everything from minor structural repair to restoring a boat that has few original components still in good shape. Most of the boats have a white oak or mahogany hardwood backbone.

According to Regan, a wood that’s being used more and more for boatbuilding is called sapele, an African hardwood that’s available in very large, high-quality pieces at a reasonable price. Soft yellow cedar is typically used for planking and decks.

Regan tries to take advantage of local woods appropriate for boat building whenever possible. “You need a certain amount of rot resistance and the wood needs to hold a finish well,” he says. “If the boat needs to be particularly lightweight, we’ll use woods that are less dense. It depends on how the boat is going to be moved.”

In general, Regan works with mill-purchased, rough-sawn wood, usually a plank about 15 to 20 feet long, at least 1”x18”, and up to four inches thick. From that, he runs the wood through jointers and planers into finished lumber. The final dimensions depend on the size of the boat.

Once the board is jointed and planed smooth, it is pushed through table saws and band saws to get curved shapes. Regan says steam bending is the fastest way to make a bent part, rather than cutting it out of sections and joining it together or gluing it from lamination into a curve.

Hull of the Zimmer launch: The launch is designed by Nelson Zimmer circa WWII. A launch is a type of boat used to ferry a small number of passengers. This particular design is well known among boatwrights, and is often referred to as the Zimmer launch, since it appears he only designed one boat of this type, although he designed many other types of boats.

Managing Wood Moisture When Steam Bending

In order to bend wood with steam, the wood needs to have a high moisture content. The moisture in the wood is what transfers the heat of the steam into the center of the wood. If the wood is dry, the heat doesn’t transfer into the wood as well, and it’s very likely to split or crack when bending.

Buying freshly-cut wood that’s still wet inside is ideal. But that can be difficult because some wood species are shipped from overseas. While kiln-drying wood helps stop the spread of insects, doing this makes it unsuitable for steam bending. But you can restore that moisture by soaking the wood, says Regan.

“If I have a dried piece of wood that I need to bend, I’ll soak it up to a week here in the bay, then I can verify the moisture content using the Wagner wood moisture meter. I know once the wood gets up to 32 percent moisture, that’s the fiber saturation point. It takes just a few seconds to get a reading.”

Regan’s been using a Wagner moisture meter for several years and still has the original battery in it.

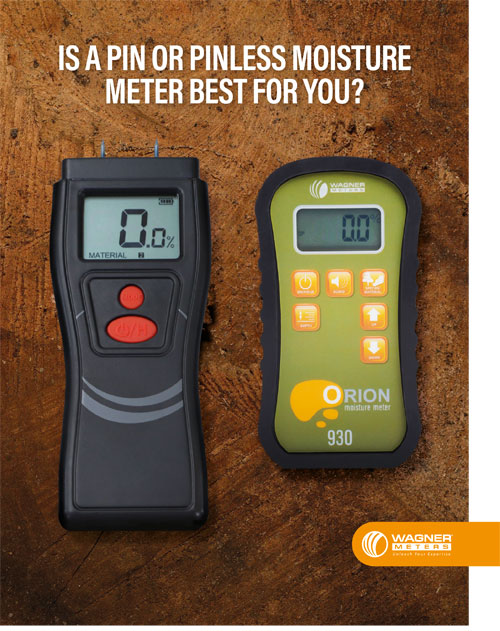

Free Download – Is a Pin or Pinless Moisture Meter Best For You?

He cautions that it’s not possible to understand how wet a piece of wood is by looking at it. A reading must be taken from the inside.

“When I was looking into steam bending, I looked into some less expensive pin-type meters, and a pin-type meter would have done the job, but it wouldn’t have been as convenient to use, and I also couldn’t use it on cosmetically critical surfaces. So I decided on the Wagner, and I have no regrets.”

“When I was looking into steam bending, I looked into some less expensive pin-type meters, and a pin-type meter would have done the job, but it wouldn’t have been as convenient to use, and I also couldn’t use it on cosmetically critical surfaces. So I decided on the Wagner, and I have no regrets.”

In addition, Regan notes when he works with different types of wood, being able to easily adjust the meter to different species without using conversion tables and without temperature compensation was also a selling point.

Recently he contacted Wagner Meters’ customer service when he was having problems with uneven moisture readings on a boat that was curing inside a boathouse. He found out that salt water crystals can affect the moisture meter’s readings and was thankful for the insights and tips he received. “It’s the type of tool that if you don’t have it, there is no substitute for it. You can either measure moisture or you can’t.”

Tony Morgan is a senior technician for Wagner Meters, where he serves on a team for product testing, development, and also customer service and training for moisture measurement products. Along with 19 years field experience for a number of electronics companies, Tony holds a B.A. in Management and his AAS in Electronics Technology.

Related Posts via Taxonomies

Last updated on May 4th, 2021