The Importance of Moisture Measurement and Control

Superior manufacturing of cabinetry, doors, surfaces, and panels begins and ends with stringent quality control procedures that adhere to the highest standards. Customers demand products that are timeless and maintenance-free. Factors like function, elegance, and durability often determine whether a product and perhaps the product vendor succeeds or fails.

A Note From the Doctor

Gene Wengert, Professor Emeritus at the University of Wisconsin-Madison, known to woodworkers worldwide as “The Wood Doctor,” has authored eight practical books and published over 400 articles relating to wood’s relationship with moisture.

Gene Wengert, Professor Emeritus at the University of Wisconsin-Madison, known to woodworkers worldwide as “The Wood Doctor,” has authored eight practical books and published over 400 articles relating to wood’s relationship with moisture.

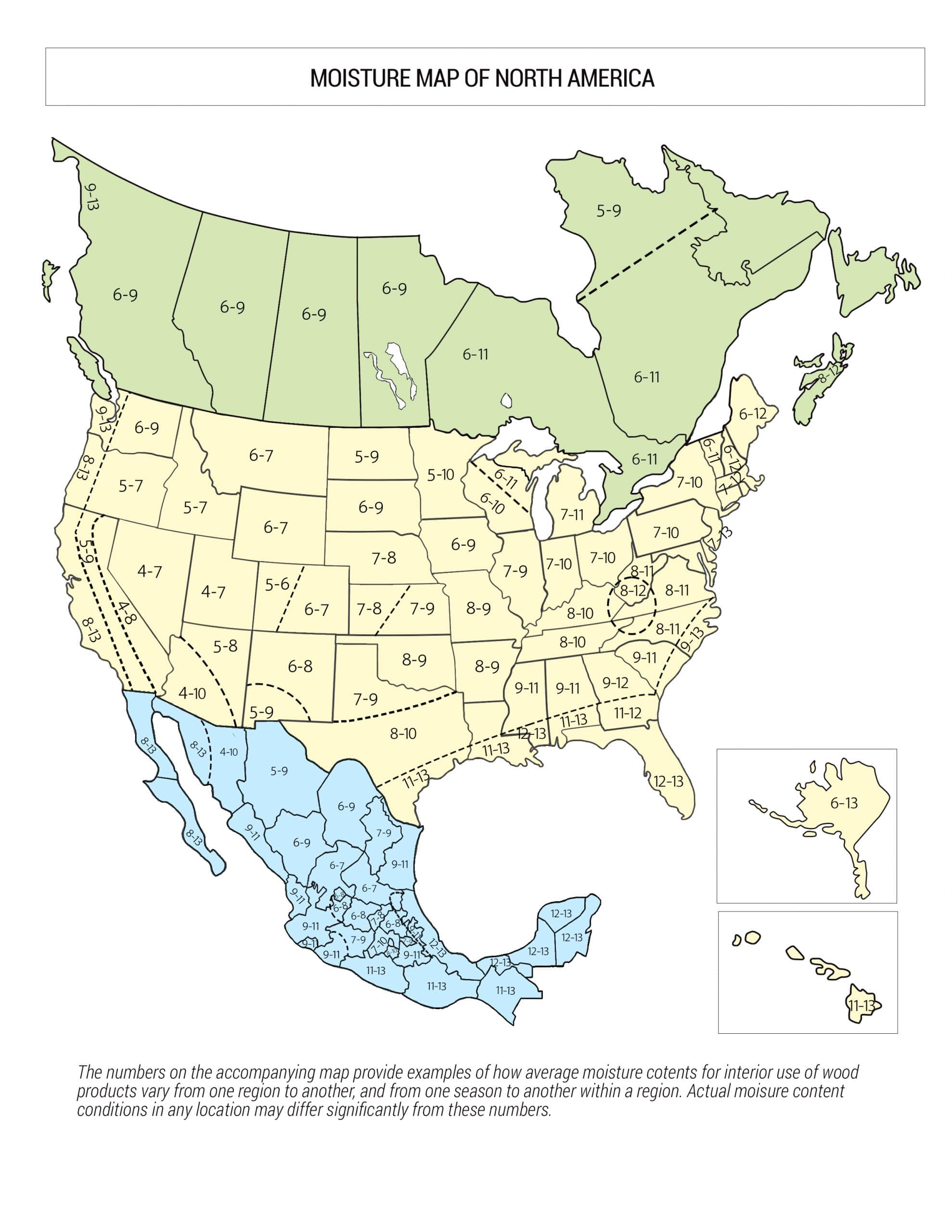

Drawing upon his years of expertise, Mr. Wengert states that “…at least 75% of wood manufacturing problems are moisture related.” A significant statistic to consider for any woodworker. But, perhaps his most important and relevant statement addressing how wood reacts to moisture is simply that “…the change in width (across the grain) will be about 1% for a 4% moisture content (MC) change (depending on species).”

When fitting pieces that require tight tolerances, it’s easy to visualize how deviations of only a couple of percentage points can lead to potentially catastrophic consequences. For medium density fiberboard (MDF), it is, perhaps, more critical for accurate moisture measurement since this type of bonded fiberboard reacts more exaggeratedly. In conditions where normal wood shrinkage would be .05%, MDF shrinkage has been shown to be .25%.¹

Accurate Moisture Measurement Instruments

Success or failure is often determined by the difference of a couple of percentage points of MC. Therefore, a consistently accurate wood moisture meter is paramount for quality control personnel concerned with mitigating the risk of moisture-related defects in finished goods or components.

Success or failure is often determined by the difference of a couple of percentage points of MC. Therefore, a consistently accurate wood moisture meter is paramount for quality control personnel concerned with mitigating the risk of moisture-related defects in finished goods or components.

Up to this point, moisture meter manufacturers have provided a calibration reference wherein, if the user suspected that the meter was out of calibration, they could determine the extent to which the meter was out of calibration. If the meter was shown to be out of calibration, the user faced a choice of either sending the unit to the manufacturer for calibration or purchasing a new meter. Both choices required extra money and time.

A NIST-Traceable Solution

Wagner Meters, an industry provider of moisture measurement instrumentation since 1965, has introduced a new line of Orion handheld pinless wood moisture meters that include an exclusive device that allows the user to calibrate the meter at their location in approximately 30 seconds.

Wagner Meters, an industry provider of moisture measurement instrumentation since 1965, has introduced a new line of Orion handheld pinless wood moisture meters that include an exclusive device that allows the user to calibrate the meter at their location in approximately 30 seconds.

Named the “On-Demand Calibrator,” the small plastic platform distinguishes itself from a “calibration reference” that merely informs the user of the calibration condition. The On-Demand Calibrator provides the means to truly calibrate the Orion pinless wood moisture meter instantly with the press of two buttons.

The Orion On-Demand Calibrator is an external and solid calibration standard, more reliable than ‘internal calibration checks’ that can be subject to the same harsh conditions as the meter and don’t test the entire system. Wagner Meters offers a NIST-traceable version of the On-Demand Calibrator to assist companies that align with strict ISO standards of excellence.

Free Download – Is a Pin or Pinless Moisture Meter Best For You?

Key Component

Wood and MDF are both hygroscopic materials that interact with moisture, either by direct exposure or in the presence of ambient relative humidity levels. Tremendous care must be taken to monitor and control the MC during the many inspections needed along the manufacturing and assembly process of cabinets, panels, doors, and surfaces.

Consistently accurate and calibrated handheld moisture meters are critical to the manufacturing process to ensure that moisture-related defects are minimized, helping minimize in-process waste and customer complaints and returns.

For more information about the Orion line of pinless wood moisture meters and their on-site calibration capability, call (541) 291-5124.

Previously published by Surface & Panel magazine.

As Sales Manager for Wagner Meters, Ron has more than 35 years of experience with instrumentation and measurement systems in different industries. In previous positions, he has served as Regional Sales Manager, Product and Projects Manager, and Sales Manager for manufacturers involved in measurement instrumentation.

Related Posts via Taxonomies

Last updated on January 5th, 2023