Wood Finishes – The Basics and Tips When Applying

It was sometime in the late 1970s when Bob Flexner opened his furniture making and restoration shop. Just like any other artisan, he felt immense satisfaction and a deep sense of pride and accomplishment in crafting and restoring furniture; naturally, he became quite good at it.

It was sometime in the late 1970s when Bob Flexner opened his furniture making and restoration shop. Just like any other artisan, he felt immense satisfaction and a deep sense of pride and accomplishment in crafting and restoring furniture; naturally, he became quite good at it.

When it came to wood finishing, however, that was a different story. Flexner admits he struggled with finishing for years. A struggle not unlike what many other woodworkers also faced then and still face today.

What Flexner discovered was that much of the available information on finishing was contradictory and misleading. He realized this was why he and other woodworkers found finishing so hard to master.

This contradictory information came from a number of sources, including the only magazine dedicated to woodworking back then, Fine Woodworking, paint store clerks, finish product reps, and even the instructions written by the manufacturers of finishing products.

Why so much misinformation?

Flexner says the answer is simple. It’s the difference between “physics” and “chemistry.”

He explains that “woodworking is physics. A manufacturer could try to sell a band saw as a table saw because it has a table on it. But they can’t get away with that because everybody knows what a band saw is and what a table saw is, and you can see it.”

He explains that “woodworking is physics. A manufacturer could try to sell a band saw as a table saw because it has a table on it. But they can’t get away with that because everybody knows what a band saw is and what a table saw is, and you can see it.”

“But a can of finish, that’s chemistry. And you can’t see what the chemistry is. So a manufacturer can sell you a can of teak oil when it really isn’t teak oil. It may only be regular varnish thinned with paint thinner or just regular mineral oil. Yet they call it teak oil. You don’t know.”

As a result, Flexner says this lack of visual confirmation enabled mythologies about finishing to develop that were spread from person to person, or “expert” to “expert.”

Flexner knows this all too well. After years of struggling with wood finishing, he began researching the subject at a major university library. There he studied at length the chemistry and technology of all coatings – paints, stains, and finishes.

Eventually, he learned to define the various types of finishes and their respective qualities, as well as identify what a finish product really was versus what the manufacturer claimed it to be. In short, he learned to separate the contradictory information, misleading labeling, and even deliberate deception from what was fact.

Armed with this knowledge, he went on to become one of the world’s leading authorities on wood finishing. His book, Understanding Wood Finishing, has sold 400,000 copies since being published in 1994. Other books such as Flexner on Finishing and Wood Finishing 101, plus hundreds of magazine articles, followed.

Wood Finishing Basics

To help woodworkers better understand wood finishes and some of the issues surrounding their applications, Flexner commented on some of the wood finishing basics.

He defines the term “finish” as a clear, transparent coating that’s applied in liquid form to wood by brushing, spraying, or wiping it on with a cloth. Sometimes, though, “finish” can mean an entire series of coats – meaning stain, one or more coats of clear finish, and maybe some coloring steps in between these coats.

A finish benefits wood in two basic ways: protection and decoration.

Protection means protection from moisture, either in a liquid or vapor form (humidity), or protection from scratches, dirt, and wear. The thicker the finish, the more moisture-resistant it is.

For example, three coats are more protective than one or two. Some finishes, however, offer no significant thickness or protection. That’s the case with wax, boiled linseed oil, and 100% tung oil. Each dries soft and gummy, so all the excess has to be wiped off after each application to maintain a workable surface. Doing this, however, provides insufficient thickness or protection.

Decoration means the finish showcases the wood’s natural beauty, color, figure patterns, grain, and depth. It also enhances the wood’s appearance by hiding defects.

There are several types of wood finishes. Here are the basic ones most woodworkers use:

- Oil (100% tung oil, boiled linseed oil, and blends of these oils and varnish)

- Oil-based varnish (including alkyd, polyurethane, spar, wiping and gel varnish)

- Water-based finish (a finish that thins and cleans up with water)

- Shellac

- Lacquer

Paint, too, is a wood finish, but one with enough pigment to hide the wood. Stain is also a wood finish, but one with pigment or dye plus a lot of thinner to make it easy to wipe off. What’s left simply colors the wood rather than hiding it like paint.

Deciding which finish to use on a piece of wood depends on several factors. For instance, a woodworker might want to select a particular finish over the others if it offers greater durability, is easier to use, provides either a certain color or no color, dries faster, or emits the least amount of toxic fumes.

Deciding which finish to use on a piece of wood depends on several factors. For instance, a woodworker might want to select a particular finish over the others if it offers greater durability, is easier to use, provides either a certain color or no color, dries faster, or emits the least amount of toxic fumes.

Durability is the strength of the finish film itself to resist being damaged. For example, polyurethane, initially introduced in the 1960s as a no-wax floor finish, would be a good durable finish.

Since a polyurethane finish dries slowly, it can be brushed on. Alternatives for someone wanting to spray on a durable finish would be to use a pre-catalyzed or catalyzed lacquer or conversion varnish. These are all called catalyzed finishes and are a little bit different than lacquer. Although they have different resins in them, they dry fast like lacquer and are just as durable or even more so than polyurethane.

If ease of use is important, then a simple wipe-on finish like Danish oil or an oil varnish blend can be used. A wipe on and wipe off product is much easier to use than working with a brush or a spray gun.

Color is another consideration when choosing a finish. Water-based finishes, which are acrylics, give the wood no color nor do they darken as they age. They work well on lighter woods such as maple, birch or pine.

If finishing a darker wood, such as walnut, mahogany or cherry, then one of the other finishes such as shellac or lacquer is better. They give the wood somewhat of a yellowish to yellow-orange coloring. They also make the wood look richer and continue to darken as they age.

If drying time is important, shellac and lacquer finishes dry the fastest followed by water-based finishes. Varnish and oil take longer to dry, usually overnight in a warm room.

Since lacquer dries the fastest, it works great when applied by a spray gun. Shellac and water-based finishes dry fast too, and can be either sprayed or brushed on.

Less toxicity can be another factor in selecting a finish. One of the most toxic finishes is lacquer. It requires good ventilation. Some woodworkers find oil-based varnish thinned with paint thinner to be objectionable, but it’s not especially toxic.

The least toxic finishes are boiled linseed oil and 100% tung oil. They’re followed by water-based finishes and shellac.

Before the Wood Finish Goes On…

As already stated, one of the benefits of applying a wood finish is its protection against moisture and humidity. However, problems could occur if the wood object is not properly dried before adding a finish.

Flexner says, “You want the wood to attain its equilibrium moisture content (EMC) with the surrounding atmosphere so that it doesn’t shrink and swell. You might notice sometimes a cabinet door with a frame around the outside and a panel on the inside after the whole door has been finished or painted. If the wood wasn’t dry enough for that atmosphere, over time the panel shrinks and you have a line on each side where there’s no finish or paint.”

“So it’s important that you check and use a moisture meter, and that you check the wood for its moisture content (MC). You can use the EMC tables that will tell you what the MC should be for that atmosphere. Usually around 6 to 8%.”

TIP: Woodworkers can now easily calculate EMC (and troubleshoot wood moisture problems) using the free Wagner Wood H20 app. There are no complicated on-screen tables or computing – just a quick and simple calculation of necessary temperature and relative humidity for EMC. To download the app, click here.

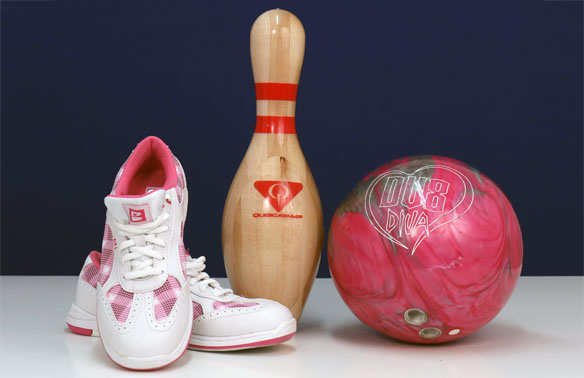

An excellent illustration of this concern for moisture before applying a protective coat is seen in the construction of bowling pins. Bowling pins are made of hard maple because of its great strength and distinctive sound when the pins crash. During the manufacturing process, several pieces of the maple are glued together. However, if the maple pieces are not dried to the proper MC, the glued joints would fail and they would fall apart.

An excellent illustration of this concern for moisture before applying a protective coat is seen in the construction of bowling pins. Bowling pins are made of hard maple because of its great strength and distinctive sound when the pins crash. During the manufacturing process, several pieces of the maple are glued together. However, if the maple pieces are not dried to the proper MC, the glued joints would fail and they would fall apart.

QubicaAMF Purchasing Manager Chet Moore explains how his company addresses this issue. “Essentially, we glue several pieces of maple together, so they have to be dry enough to be glued. But we don’t dry it quite as low as a furniture maker. We try to keep it at a certain moisture level to optimize the production process and the quality of the pin. But if the correct moisture level is not attained, the glued pieces won’t stay together. That joint will eventually fail,” he says.

To prevent this from happening, QubicaAMF uses a Wagner wood moisture meter throughout the kiln drying process. The Wagner meter, highly acclaimed for its accuracy, comes with a special attachment that the kiln operator can slide into the center of the wood bundles before they are placed in the onsite drying kilns.

This enables the kiln operator to check the different layers in the bundles as they’re drying. Since the Wagner meter is pinless, it leaves no holes in the maple.

Once the wood is dried to the ideal MC level, they can glue the pieces and then coat it with a plastic called Surlyn®. This coating protects the maple from damage and keeps out any unwanted moisture, thereby extending pin life.

Applying a Finish

After an object is made and it’s time to apply a finish, Flexner says the MC of the wood becomes less of an issue; that is, unless the MC is so high (almost wet to the touch) that it causes a problem with the finish.

The thicker the finish that’s applied, the better it’s going to resist moisture or humidity exchange, but Flexner cautions woodworkers about applying a finish that’s too thick – typically, more than three coats. What happens is that the finish deteriorates and cracks faster.

The exception would be a poured-on epoxy finish – like what some restaurants use on their dining tables. The boards in these tables show no visible shrinkage or expansion because the epoxy finish is so thick that it just stops the change almost entirely. But, of course, epoxy is not a very functional finish for a cabinet or some fine pieces of furniture.

While a regular finish can greatly minimize the shrinkage and expansion of wood, the wood will still undergo some movement. This often occurs during the change of seasons or if a piece of furniture is moved from a very dry location, like Phoenix, to a much more humid locale, like Miami, or vice versa.

For example, in winter and summer, when the air is drier due to a heater or air conditioner running, the wood shrinks. In the fall and spring, when HVAC units may not be on or when windows are left open, the wood can expand but again, not to the extent that it normally would if there were no finish on the wood.

Flexner also notes that the first coat of any finish seals the wood. In effect, the finish stops up the pores in the wood so that the next coat of finish, or any other liquid for that matter, doesn’t penetrate easily.

This first application of finish raises the wood’s grain so that it feels rough. Rubbing sandpaper lightly over the rough surface will make it feel smooth.

This first application of finish raises the wood’s grain so that it feels rough. Rubbing sandpaper lightly over the rough surface will make it feel smooth.

Nothing else needs to be done to the wood unless, after this first coat, one of two issues need to be addressed.

The first issue involves the use of alkyd varnish and lacquer. They gum up sandpaper when the wood is sanded, so a sanding sealer will be needed. Flexner notes that sanding sealers weaken the finish and should be used only when finishing a large project or doing production work.

The second issue may involve problems in the wood such as resinous knots in softwoods. This problem can be corrected by using shellac for the first coat.

Free Download – Is a Pin or Pinless Moisture Meter Best For You?

Closing Comments

Obviously, this article only skims the surface of all there is to know about wood finishing. For anyone wanting a more in-depth coverage of finishing, read Flexner’s book Understanding Wood Finishing.

For the amateur woodworker or someone wanting to do basic finishing, Flexner’s book Wood Finishing 101 would be ideal. It’s not as comprehensive as Understanding Wood Finishing, but it comes with plenty of photos and step-by-step illustrations.

Larry Loffer is a senior technician at Wagner Meters, where he has over 30 years of experience in wood moisture measurement. With a degree in Computer Systems, Larry is involved in both hardware and software development of wood moisture measurement solutions.

Related Posts via Taxonomies

Last updated on April 21st, 2021

Hi Jason,

I enjoyed reading your article but am having a hard time figuring out what wood protection product/sealer to use on a 4′ x 6′ outdoor 2-sided sign, 1 1/2″ thick. The sign is made of red oak and when I tried water white sealers (tried on 2 different occasions after sanding the wood down to it’s bare state), the wood just darkens too much that the letters blend in. The letters on the sign are painted black. The person who made this sign 20+ years ago was able to achieve the more natural wood look, not darkened, thus the words on the sign stood out. I’m guessing some clear varnish/top coat was used, which lasted a couple years before applying other sealants to it. I am unable to achieve that same effect. Appreciate any recommendations you may have! Thank you!

Hi there, thank you for the article. I’m working on an old walnut desk that had some damage and an ugly finish. I’ve managed to strip the whole thing and am in love with the colours of the wood and would like to protect it while changing as little of it as possible. Could you advise on which products I should use to get there (the least darkening/changing the colours of the wood)? This is my first wood project and it’s been really exciting but I’m lost when it comes to this point.

Thank you so much for your help!

Sara,

The best way to preserve the wood and keep its color is a standard varathane. I would check with the companies that provide these products to determine their best use.

Thanks for writing in.

Hi- l am trying to recall the product l used to finish a 1x 6 piece of natural Hickory making a cap and mounted on a foyer half wall. After sanding l applied several coats of polyurethane. As a final step l applied a clear liquid product that produced a smooth, protective finish that enhanced the woods color variations even through the polyurethane. The exotic wood company apparently went out of business so retracing those steps fell apart. I have searched my house and cannot locate. Does any of that ring a product bell? If not please recommend a top coating for a 3/4 inch Maple veneer plywood (cabinet grade) that l am using as a 7’x25”” – 6 x 48” L shaped desk top w/ 4 coats of polyurethane clear finish.

Thanks, Don

Don,

None of what you are speaking about rings any bells here. It’s very difficult to recommend any finishes or applications of your hardwood project. Check with the manufactures for proper application processes.

Getting to be the rainy season in the Pacific NW and I am working in an unconditioned shop. Working with quarter sawn white oak that has been stored for some years in the local environment so it is starting pretty well dried. About to finish glued up table tops for side tables.

Should I just go ahead and finish them or bring them inside the much drier air of the house for some period of time first? If so how long? Don’t want them to start moving before I get them sealed.

They will be in our bedroom upstairs in our woodstove heated house with pretty low humidity in the evenings and we get pretty significant swings in relative humidity from summer to winter.

Rich,

As you know its always best to have the material in the area it will be living after installation. Most people’s shop or garage has heat so the RH should be fairly the same. I would make sure the conditions are as close to the final resting place of the item you are building.

Thank you for writing in.

this is a great tips for those who is confuse on adding finish to woods. Thanks for sharing this to us.

hi i have cls for my cider press cage, as i want to keep toxicity down, should i treat the wood with something or keep it bare and just let it dry out after each uses? I obviously uses sterilizing fluid on it after each use (citric acid)

many thanks.

Steven

Thank you for the great info! I have never stained anything before now, so please excuse the ignorance.

I live in Phoenix, AZ. I have a new spinning wheel made in New Zealand that had various types of wood (most seem very soft) used in the production process. I stained it with 2 thin layers of minwax oil based wood finish (Colonial Maple with 8ml’s of Cherry Mahogany mixed in) and let it dry for 24 hours. I would like to put a good protective sealer/finish on it, but I am concerned about it drying out over time in our low humidity climate. We do have quick bursts of humidity during monsoon season but they are far & few between. Having the wood shrink over time would negatively effect the function of parts of the wheel. If I use a coat of polyurethane, will I still be able to rehydrate the wood if it starts to “dry out” in the future? Or will the polyurethane seal it so that if the wood shrinks, it will be a permanent change to the wood?

What would be the best way to seal/protect the wood from dehydrating, scratches, normal wear & tear, etc. in this scenario? Is it possible to make it water resistant, while maintaining the ability to keep it hydrated over time? Oxymoron, I know, but I want to finish it to make it last & keep it’s function for as long as possible. Thank you so much for helping this newbie!! It is very much appreciated!

Emily

Hello,

I would suggest getting in touch with one of the local woodworking clubs. They are much more familiar with the climate. Here is just a few:

https://azwoodworkers.org/

https://scwwoodshop.com/

https://woodshop.scwclubs.com/

http://www.oldaveswoodshop.com/AZ.php

This is a fantastic article. I have been in the wood finishing business for 20 years. I always have the challenge of trying to explain to my clients the different finishing combinations on the wood they have in their home. For me this article was an easy to understand synopsis of some basic options. I am going to bookmark this so that I can share it clients who are struggling to understand wood finishing options. Thanks for the great content!

Great article! As for me I prefer Lacquers for wood finish also most professionals still regard lacquer as the best all-around finish for wood because it dries fast, imparts an incredible depth and richness to the wood, exhibits moderate to excellent durability (depending on the type used) and rubs out well.

Hi,

What a great article thank you! I live in the UK (very rainy Scotland) and am in the process of building a brick outdoor seating area. I’ve had Douglas Fir cut to size for my seats and have almost decided to use either boiled Linseed oil or Swiss oil to protect and preserve the brand new wood and also make it a bit darker. My question is this… can I then put polyurethane over the oil in order to protect it from the horrible weather? If the answer is yes, what about re oiling it every year or two? Should I instead just use the polyurethane with no oil at all? Or will the oil itself with no varnish suffice?

Pauline,

‘The author of the article basically pulled together (basically, compiling) some research heavily focused on Flexner’s vast experience, and at the end of the article the author highly recommends Flexner’s Wood Finishing 101. Lastly, as the article mentions, correct moisture content, not only relating to the environment where the wood will inhabit, but also the correct moisture content for the finish product to be used.’

Ron

I have been working on a vintage mahogany dining table for a while and can’t overcome numerous problems. First, when I sanded the old finish and applied a dark stain. Once stained I noticed a big variation in color that wasn’t in the original finish. So I applied more stain to the boards that were lighter. The result worked but wasn’t not as even as original. Then I finished the project with polyurethane which was a disaster.

The finish kept separating around some of the boards with more wood grain. The help at the local paint store said this happens when an old piece has been polished with silicone based products like Pledge. I started all over again sanding the table again and restaining. This time I used wood conditioner before staining and got a more satisfying result. Then I applied a sealer over the stain and am now ready for the finish.

I am afraid to apply the finish and want to know the best finish for the project, should I use an oil rub like tung oil or a polycrylic for more protection? Thanks, looking forward to a finished project, Hope

The only advice I can offer is to match the “base” of all the products used. For example, if the stain was an oil-based stain, use an oil-based protectant such polyurethane. Never mix oil-based and water-based products on the same piece of furniture.

Moreover, since the table was sealed with a “Sealant”, this could render an oil-based rub ineffective as it may not penetrate the surface. In my opinion, a sealant is more often than not viewed as a final finish layer.

Hope this helps.

This advice comes from a hobbyist and should not be interpreted as expert in nature. Please consult additional sources and remember to always test a process on an area that is unnoticeable (such as the underside of a table) before proceeding to finish the entire project. Finally, always consult the manufacturer’s instructions on each product that is to be applied.

Hello,

I made an outdoor sign using a wood picket fence (new). I stained (grey) and burnt the wood. I would really like to protect it from the elements without a yellow finish. matte would be ideal.

what would you suggest?

Thank You,

Christine

Hi Christine,

I would visit your local paint store and tell them you want a matte finish.

Let them know the work that you have done so far.

They should be able to get you the right product.

Hi thank you for this article. I am looking (for years) for a finish for oak countertops that won’t darken the wood. The oil that came with it made it too dark so I used a water based varnish but this has not given enough protection at sink area. Please help!

Josephine,

Any finish will generally darken the wood to some extent. Some oils (such as linseed and tung) can provide nice protection. You might also consider a better clear varnish with obviously multiple coats.

Greetings Larry, GREAT article by the way. I have a friend who makes Baseball Bats out of Ash and Maple. They advertising their bats as “extremely hard bats”. With this said, is there a recommended finish, technique or wait time (dependent on the finish or technique suggested) you would suggest to further warrant the hardness of the bat? Thank you! Tom

Tom, unfortunately, we are not experts in bat surface hardness techniques but here is a good article (https://tht.fangraphs.com/whats-in-a-bat-inside-the-process-of-bat-manufacturing/), and it does very briefly mention finish and compression of the fibers in a wooden bat. Typically, density is also a factor in a wood species durability.

Hi Larry,

Is dried water based lacquer toxic when scratched off and eaten?

If you’re not sure, can you suggest a way to find out ?

Thank You!

– John Burley

Hi John,

Lacquer is a clear or colored coating (called a varnish) that is often used to give wooden surfaces a glossy look. Lacquer is dangerous to swallow. Breathing in the fumes for a long period is also harmful.

Poison control center – emergency number for anywhere in the U.S.: 1-800-222-1222

This national hotline number will let you talk to experts in poisoning. This is a free and confidential service. All local poison control centers in the United States use this national number. You should call if you have any questions about poisoning or poison prevention. You can call 24 hours a day, 7 days a week, 365 days a year. For more information, contact the American Association of Poison Control Centers – http://www.aapcc.org.

Hope this helps.

Hi Larry. Great Article.

We are starting to import furniture from Indonesia. Mostly large suar wood slabs and suar and recycled teak furniture.

I have been doing alot of research on RH and it’s effects of furniture. I have also been speaking to alot of different people, all of whom seem to have different opinions.

Our company is located in Florida and will be selling across the US. We currently keep our inventory in a non climate controlled warehouse.

1. I have been told by some to get the MC down to about 5 or 6% to avoid mold issues, but now after reading your article I am concerned about this. Would it make more sense to dry it down to 6 to 8%, even though we are in Florida or 12 to 13%?

2. Since our warehouse is not climate controlled do you suspect this to be a problem?

3. We are going a step above (at least I think we are from research and experience) and having the finisher in Indonesia use varnish instead of melamine as they typically use. The varnish will be applied in 2 coats with sanding in between. This is costing me extra to do, but I think it is well worth it.

4. Would it be better to leave the RH lower to allow expansion just in case or to keep it high with the risk of contraction?

5. Which tester would you recommend for this type of application?

I look forward to your response.

Mike, Wood will swell or shrink when gaining or losing moisture. This can be a problem if it is made into a finished product. Since Florida has high humidity, the target moisture content is higher than other parts of the country. This is not a problem as long as the wood is acclimated to the proper moisture content of the environment it will be in. Wagner has an APP for this called “WoodH2O”. This will calculate the proper moisture content given ambient conditions. Also, see our new line of Orion meters.

I’m going to finish a piece of furniture with finishing oil (called Liberon Finishing Oil), but it seems to contain a lot of solvents, so I’d prefer to do it outside, and let it dry outside over night. There will be a roof above to protect from rain. Only problem is, after an almost completely dry summer, suddenly we are getting rapidly changing weather in my town (Oslo), alternating between dry and humid, with occasional periods of rain.

It’s easy to get perfect conditions at the time of applying the first coat, but during the night there will be lower temperatures, down to 10 degrees celsius (50 F), and humidity up to 95%. Can this be a problem, or will it be sufficiently sealed after the first coat has died for about 5-6 hours in ideal conditions, so that is less of an issue?

Mr. Holmen,

The first coat should be enough to prevent moisture from absorbing into the wood, especially since it is just for one night. It typically takes many days for furniture-grade wood to absorb enough moisture to be a problem.

This is a very great suggestion particularly to those new to blogosphere, short and accurate information. Thanks for sharing this one. A must read the article.

I am trying to replicate the cracked finish on an old commercial oak display case for pieces that need to be replaced which were missing.I would like to be able to match both color and the fine cracking. What would you suggest?

Hi Don,

Because of the complexities involved with wood finishing, I recommend getting Bob’s book called “Understanding Wood Finishing”.

You might also try refinishing websites such as this: https://www.pinterest.com/explore/refinished-furniture/

Hi Larry,

I am refinishing six panel interior pine doors that have experienced some nicks and bruises. The doors, which are more than twenty years old, have a nearly natural finish that is a rich umber color with a nearly flat finish. I’ve found that over sanding damaged areas cuts down through the finish to the much whiter surface on some of the lighter pine. I would like to avoid sanding as much as possible, but it is deemed necessary in areas and I’m seeking recommendations for a ‘yellowing’ fast dry finish that is nearly flat. I’ve tried several finishes and had the best finish results with Minwax Water Based Polycrylic – Clear Matte. We can live with the fact that the Clear Matte is not as flat a finish as our doors currently have, but this product has no yellowing, so some of the sanded areas stick out like a sore thumb. I have twenty doors that need some level of attention, but full restoration of all these doors really isn’t in my scope of desire.

Thanks for your advice,

Frank

Hi Frank,

Thank you for reading my article. Since this is a re-finishing question, and not really associated with moisture content, please consult other resources. I have found a couple:

http://www.diynetwork.com/how-to/make-and-decorate/decorating/how-to-tell-if-wood-furniture-is-worth-refinishing

http://www.kilz.com/projects/refinish-a-door?&gclid=EAIaIQobChMI1or6iuPK1gIVTlx-Ch33xwJhEAAYASAAEgJzyPD_BwE

Thank you,

Larry

Hi Larry,

I’m finishing a brand new pantry in a small room with a window that is very drafty. I stained the entire room. It’s made of old reclaimed pine. I usually use varnishes. I’m going to use the new varnish from Fine Finishes of Europe. We’ve got some hot and humid weather coming. 90 degrees and very humid. I bought a MC meter and a meter for the room’s dew point, humidity and temp. What would be an ok room humidity level to apply my varnish. The wood is dry.

Thanks:)

Ebon

Ebon,

A general guideline for safe varnishing conditions is 50 to 80 degrees Fahrenheit and 45 to 55 percent humidity. Always a good idea to check with the manufacturer of the varnish as well.

Larry

We recently had new red oak installed in our house, which was stained and had a second clear coat applied Sunday afternoon. I’d like to move the furniture back into the newly floored rooms on Tuesday afternoon, two days later. Will the weight of the furniture have any ill-effect on the finish? Or is two days enough time to wait to refurnish the rooms?

Many thanks,

-Gabe

Hi Gabe,

I would suggest that you check with the installer, or with the clear coat manufacturer.

Despite observing drying times, can a good wood stain on a bookshelf still damage the books? Thank you. -RC

Hello,

By using a moisture meter throughout the process of staining and finishing furniture, many moisture-related problems can be avoided. There are many factors that can affect drying times for a stain. Higher relative humidity (RH), high moisture content (MC) of the wood, and lower temperatures can add to the drying time.

As for the staining of the books, this can also be caused by a finish failure due to not using enough coats or not allowing sufficient drying times between coats.

Thanks,

Tony

We have two whiskey barrels that we are going to use for out master bathroom vanitys. They are not sealed at the moment and do quite a bit of shrinking and the bands come loose so much so that they fall to the floor. Any advice would be much appreciated as to what we can do to keep the MC where the bands will stay tight. Thank you in advance.

Rebecca Moseley

Rebecca,

When in use, whiskey barrels are very moist throughout. As you know, when wood is wet it expands and it shrinks when dried out.

The only way to keep the original bands is to introduce more water/moisture into the wood of the barrel.

This high moisture would be difficult to maintain in a dry house environment. It may be easier to use smaller bands.